Le port de Ras Laffan, géré et réglementé par Qatar Petroleum (QP), est situé sur la côte nord-est du Qatar. Le port a été conçu comme une installation d’exportation de gaz naturel liquéfié (GNL), de gaz de pétrole liquéfié (GPL), de condensats, de produits pétroliers et de soufre.

Les postes d’amarrage GNL 3 et 4 peuvent accueillir des navires GNL d’un déplacement allant jusqu’à 185 000 t et d’un tirant d’eau maximal de 12,5 m.

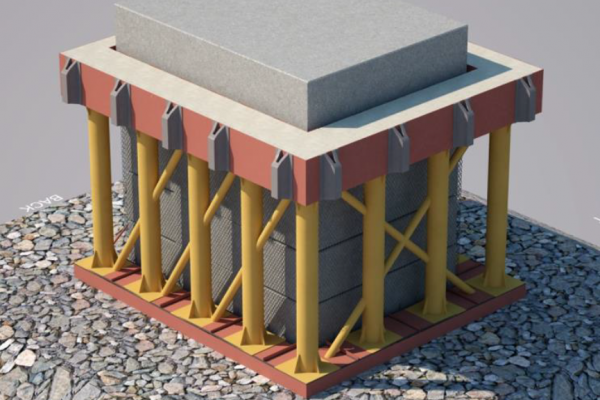

Le poste d’amarrage GNL 3 a été construit en 2004 tandis que le poste d’amarrage GNL 4 en 2006. Tous deux ont des agencements de postes d’amarrage symétriques « T-Ilot » comprenant des structures de type gravité en parpaings de béton.

L’entretien des postes d’amarrage par la COMPAGNIE en 2013 a identifié la formation de fissures dans les ducs d’amarrage MD3D et MD3E. La cause profonde identifiée des fissures est la formation retardée d’ettringite (DEF).

D’après le dernier rapport d’enquête de plongée CH2M d’octobre 2017 fourni par COMPANY, il y a 28 fissures associées au DEF dans MD3D et celles-ci sont limitées aux deux blocs de béton de masse supérieurs situés sous le bloc de couverture et dans le bloc de béton de masse inférieur dans MD3E